Solar park maintenance.

However, the maintenance of these systems is not just a matter of prevention - it is a key factor for maximizing energy production and protecting the investment. Over time, every component - from the panels to the connecting cables and inverters - is exposed to the influence of the environment: high temperatures, dust, moisture, corrosion, mechanical stress, and natural aging. The accumulation of dirt, the appearance of microcracks, cell defects, or poor electrical connections can remain unnoticed for months if there is no systematic control.

Without regular inspection, even seemingly insignificant anomalies can lead to serious consequences for the efficiency and long-term operation of the solar system:

- ⚡Loss of energy efficiency.

- ⚖️Uneven system load.

- 💸Damages with high repair costs.

- Shortened installation life.

- 🔥Risks of fire or electric shocks.

Limitations of traditional methods for photovoltaic system inspection.

Before the introduction of drone technologies, the maintenance of photovoltaic installations relied on outdated and labor intensive approaches, including the following:

- 🔍Visual inspection by technicians, which is often superficial and subjective.

- ⏳ Manual measurements with thermographic cameras, requiring time, human resources, and physical access to every panel.

- ⚡ Electrical tests of inverters and individual strings, which do not always detect hidden or intermittent defects.

These methods are associated with a number of serious disadvantages:

- 🐢 Extremely slow and labor intensive - traversing hundreds of acres of panels can take weeks, even months for larger installations.

- 💸 High costs for labor and equipment without a guarantee of full and precise diagnostics.

- 🚫 Limited accessibility - hard to-reach places often remain uninspected or are overlooked.

- ⚠️ Potential risk to personnel working outdoors in high temperatures or in areas with high-voltage electricity.

- 🔌 Necessity of shutting down the system, which leads to loss of production and additional financial losses.

How do drones transform the inspection of solar panels?

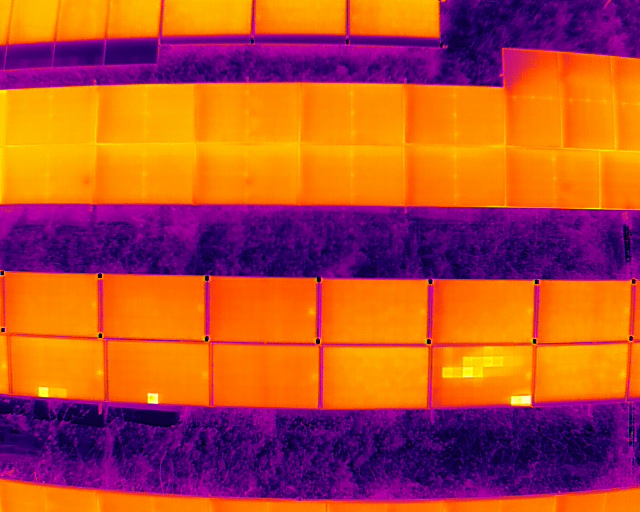

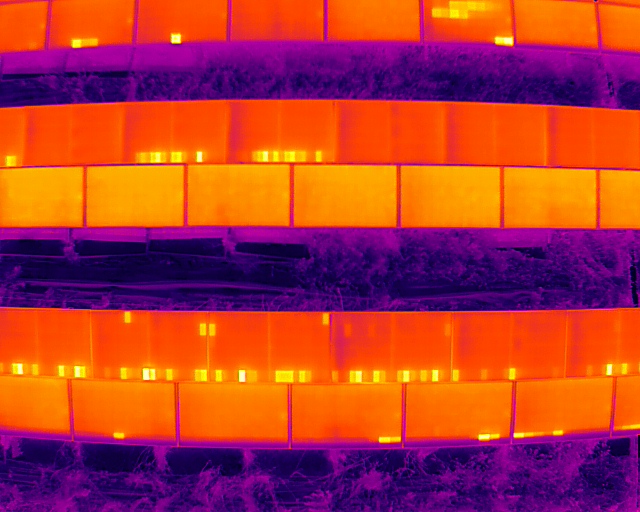

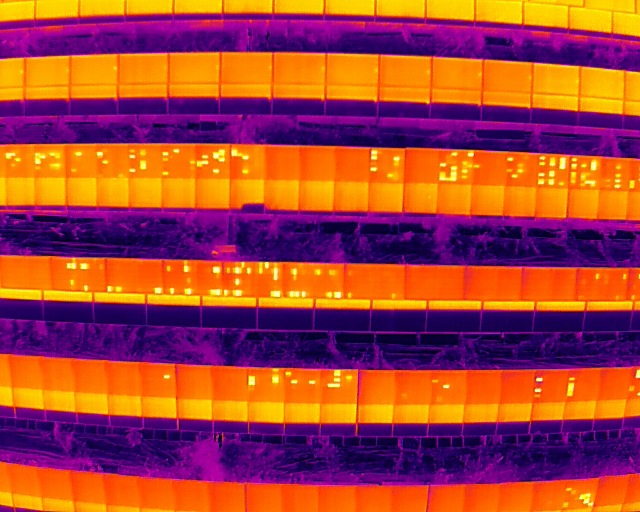

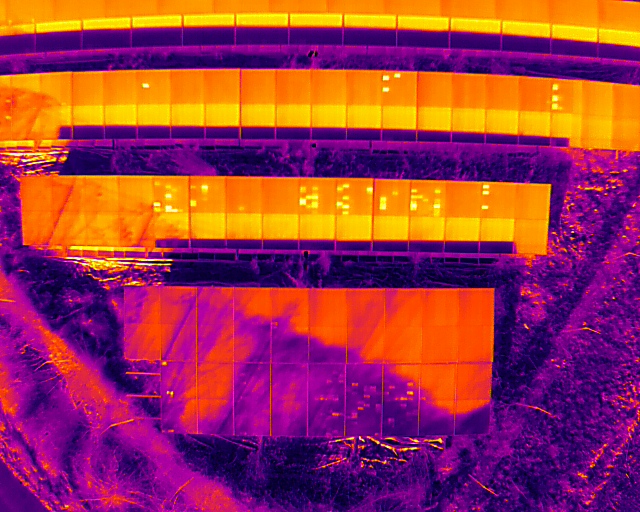

Modern industrial drones do not just improve traditional methods - they revolutionize the entire process of photovoltaic system maintenance. From the first, simpler drones used years ago, to today's high tech solutions, the evolution is enormous. Today we use platforms equipped with high resolution thermal and RGB cameras, GPS precise navigation, and numerous software improvements. Even the newest drones have built in artificial intelligence algorithms that further improve the quality of work.

Data collection on the current state of the power plant is no longer a manual process. Through pre-set settings and a flight plan, drones collect the necessary data for technical analysis and a report on the condition of the power plant extremely quickly and precisely, reducing the risk of human errors made during manual capture methods. The result provides the solar park owner with a complete real-time picture, with the possibility of traceability and analysis over time.

Drones provide the following:

✅ Speed — Surveying a megawatt-class solar park in a matter of hours instead of days.

✅ Precision — High-resolution infrared imaging detects even the most insignificant temperature deviations.

✅ Safety — No need for physical access or contact with the panels.

✅ Continuous operation — There is no interruption of electricity production during the inspection.

✅ Lower costs — Optimization of labor, minimization of losses, and timely diagnostics.

What defects can be detected through a drone inspection?

| Defects | Impact on the system |

|---|---|

| Hotspots | Local power loss, risk of fire, and degradation. |

| Microcracks | Reduced performance and frequent malfunctions |

| Damaged connections | Unstable operation and interruptions |

| Shading | Significant reduction in production across an entire string |

| PID effect | Significant power loss, permanent degradation. |

| Mechanical damage | Damage from hail, storm, or installation defect |

| Defective cell | Gradual panel deterioration, inefficiency |

| Defective bypass diode | Partial power loss, overheating, stress on cells |

| Poor electrical connection | Increased losses, thermal risk, interruptions |

| Inactive string | Complete loss of production from a given string |

| Delamination | Long term degradation, increased risk of short circuit |

| Defective junction box | Risk of fire, power outage |

How often should a thermal drone inspection be done?

🗓️ Recommended frequency:

- 📅🔄1️⃣ At least once a year for standard systems.

- 📅🔄2️⃣ Twice a year for large solar parks.

🕵️♂️ The inspection is mandatory:

- 🌧️🌪️ After strong winds, hailstorms, or extreme weather conditions.

- 📉❓ In case of suspected drop in yield.

- 🛠️🔆 After initial installation or system expansion.

Regular inspection means peace of mind and protection of your investment.

Vayo Drones – Your partner for drone inspection of solar parks.

We offer a complete professional service for thermal drone inspection, including the following:

- 📡 High-precision infrared and RGB cameras.

- 🎯 Certified pilots.

- 🌍 Compliance with international standards for safety and accuracy.

- 📊 Manual creation of technical reports complying with international standards.

- 🎯 Our mission is to help you maintain your photovoltaic system in optimal condition, without unnecessary costs and losses.

Conclusion

The inspection of solar panels with a drone is not just an innovative approach – it is a necessary investment in the long-term sustainability and efficiency of your photovoltaic installation.

✅ You protect yourself from expensive repairs.

✅ You optimize performance.

✅ You extend the life of your solar panels.

One comment

Comments are closed.