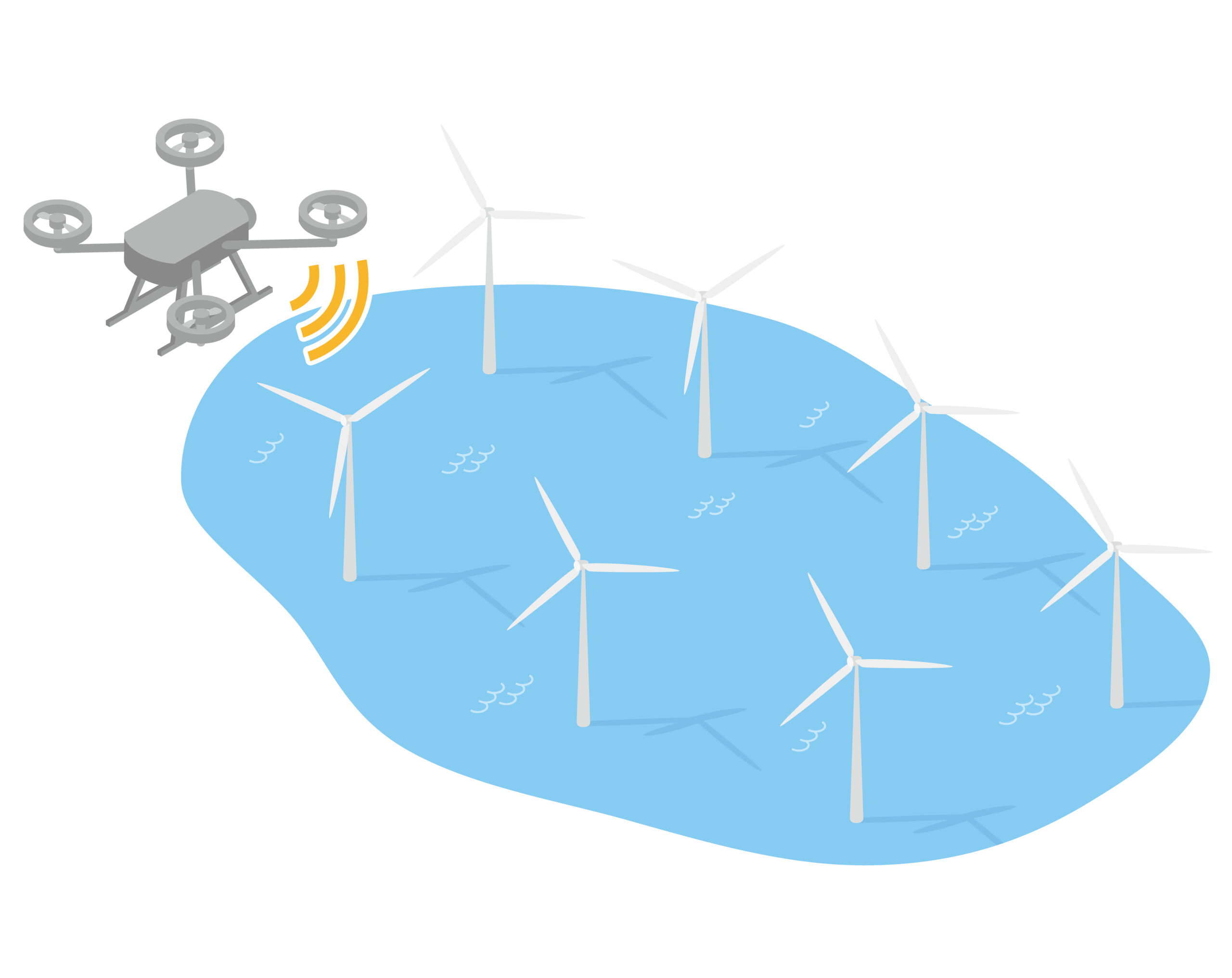

Wind turbine inspection

Drone inspection offers a safe, effective, and economical way to diagnose the condition of rotors, blades, generators, and other components.

This ensures early detection of defects and increases the operational life of the wind turbines.

Thermographic inspection

Drone inspection of wind turbines is a key method for detecting thermal and structural defects that can lead to loss of efficiency or costly damage. using infrared cameras, drones detect temperature anomalies and mechanical irregularities that are invisible to the human eye.

Timely diagnosis

We detect overheating of electrical components, cooling defects, and mechanical failures before they cause serious damage or downtime.

Safety and efficiency

The process is completely remote, requiring no human intervention on the turbines, which guarantees safety and allows for quick scanning of hard to reach areas.

Visual inspection

Visual inspection with drones provides a detailed review of the physical condition of the wind turbines. From the blades and rotor to the foundation structure. high-resolution cameras detect cracks, wear, corrosion, and other visible damage.

Precise evaluation

We check the condition of fasteners, connections, and protective coatings, providing a clear overview of the need for repair or maintenance.

Planning and reliability

Early detection of defects allows for timely maintenance planning and minimizes the risk of unexpected breakdowns and downtime.

Potential issues discovered during inspections

Thermal inspection of wind power plants

Overheating of electrical components

Low cooling efficiency

Uneven heating of the blades

Thermal anomalies in connecting parts

Overheating of transformers

Malfunction of control and protection systems

Visual inspection of wind power plants

Cracks in the blades

Corrosion of metal components

Damage to the laminated material of the blades

Wear of fastening elements

Soiling on the blades

Problems with hydraulic systems

Advantages of drone technologies for inspection

Safety

Low costs

Speed and efficiency

Access to hard to reach places

High precision and data quality

Less downtime