Power lines

Drone inspection of power lines is an innovative solution for quickly and safely assessing the

condition of the electricity transmission network. This approach saves time, minimizes risks

for personnel, and provides comprehensive data for maintenance and repair.

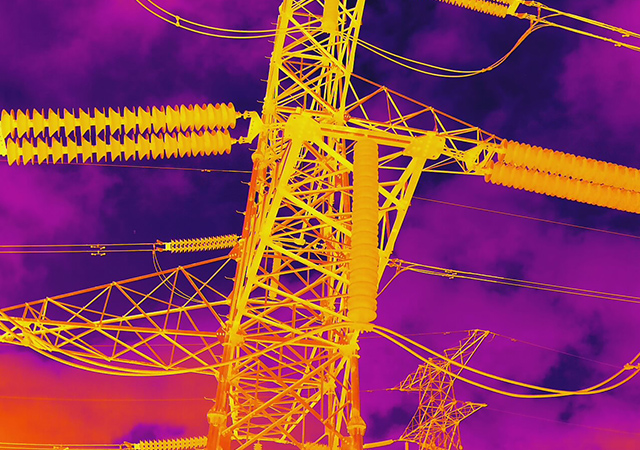

Thermographic inspection

Thermal inspection of power lines using drones is an effective method for detecting potential problems such as overheating and failures. Infrared cameras identify thermal anomalies, allowing for quick and informed decisions for the safe and efficient operation of the network.

Locating problematic zones

With the help of drones, we detect overheated areas, faulty insulators, and defective connections. Early detection prevents costly failures.

From data collection to analysis

We carry out flights over the facility, collect infrared data, and create thermal maps. These maps show temperature anomalies and assist in planning the maintenance and repair of the power lines.

Visual inspection

This type of inspection complements the thermal analysis, providing a detailed overview of the facility through the use of high-resolution cameras and sensors.

Detection of visible issues

Drones capture detailed images of cables, insulators, poles, and other components to identify corrosion, mechanical damage, wear, loose fasteners, or other defects.

Maintenance and long-term sustainability

The collected information assists in planning repairs and maintenance, minimizing the risk of incidents and ensuring the safe operation of the infrastructure.

Potential issues discovered during inspections

Thermal inspection

Overheating of conductors

Defective insulators

Broken or weak connections

Overheating of transformers

Temperature imbalances in current-carrying lines

Visual inspection

Corrosion of metal components

Cracked or broken insulators

Sagging conductors

Mechanical damage to poles

Contamination

Advantages of drone technologies for inspection

Safety

Low costs

Speed and efficiency

No disruption to service

High precision and data quality